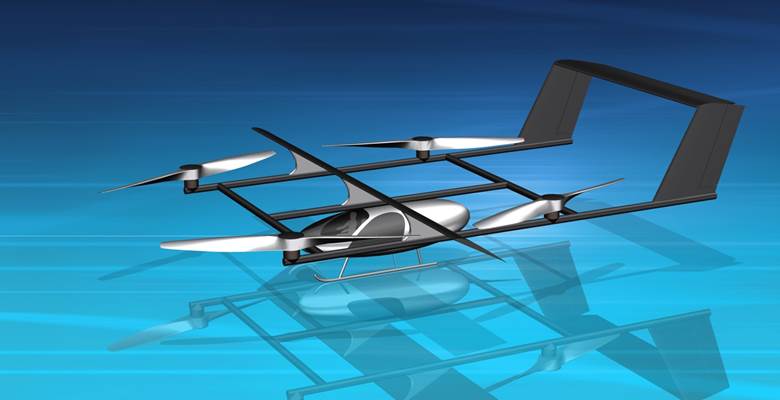

The project

of development of cargo-passenger multirotor aircraft

with a wing in oblique flux

“Pepelats”

Goal of the project

|

The goal is to create an apparatus with vertical take-off and landing for

transportation of passengers and cargo with the mass of at least 230 kg (500 lb) in automatic, semi-automatic and manual modes with

cruising speed of 200-250 km/h (125-155 mph) with range of 600 km (370

miles). We call it Pepelats. Apart from unique aerodynamic scheme we are implementing unique software

in order to increase the safety of the flights and make the piloting process

of the vehicle easier. Combining all of these characteristics, we get a fundamentally new

aircraft with unique capabilities and technical characteristics that are

inaccessible to existing aircraft. |

|

To date, a model of the promising Pepelats aircraft has been built and tested. The flight

characteristics and effectiveness of the proposed technical solutions have been

experimentally confirmed. |

Work is underway on a model with a

flight weight of 140 kg. Additional investments are required to create a

prototype. We are looking for an investor interested in the project or a

business angel.

The possibility of implementation and the relevance of

the project at the present time

|

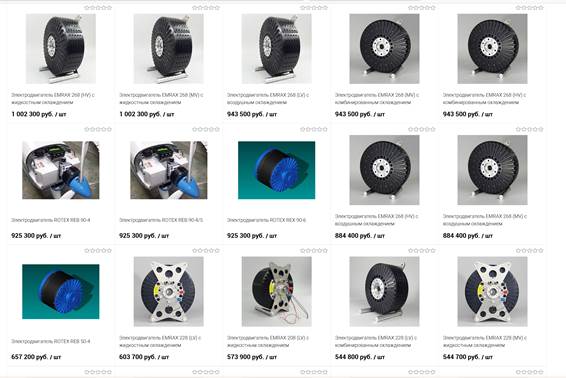

The novelty of the developed cargo-passenger

aircraft with vertical take-off and landing consists in the creation of a

promising model containing a set of technical solutions that were not

previously used together (a new utility model), but the main components of

which already exist and are mass-produced. These include: 1)

Brushless electric motors of high power up to 100 kW and more.

The progress in the development of electric

brushless motors on magnets using rare earth elements in recent years has

made it possible to obtain samples with unique parameters previously

unavailable. They are expected to fall in price as they master their

production in China 2)

Lightweight LiPo

rechargeable batteries of large capacity, currently

have one of the highest values of capacity per unit weight, with minimal

dimensions. Available values are 1.5-2 kWh with a mass

of 5-7 kg. 3)

Autonomous flight controllers have become much cheaper and become

available, critical software errors have been eliminated. 4)

Other necessary avionics, gyroscopes, flight sensors, laser and

ultrasonic rangefinders, GPS + RTK systems, etc. also fell in price. 5)

There is no doubt the possibility of automating

the process of laying a route and coordinating the movement of many unmanned

aircraft |

From a technical point of view, the creation of an

unmanned aircraft is easier than an unmanned car, and flights are safer, since

all routes are agreed and coordinated in advance. The deployment of large-scale

work in this direction is mainly hampered by the position of the state civil

aviation authorities, but some work in this direction is already underway https://bastechnology.ru/dispetcherskaja-sistema-dlja-bpla-v-kitae-evrope-rossii/

It is worth noting that the PPL pilot training program includes 270

hours of theoretical lessons or 45 training days, then about 10 hours on a

simulator and 40 hours of flight with an instructor. Passing

3 theoretical exams and at least 2 practical exams. Thus, the minimum

period for obtaining a pilot's license is theoretically 3.5 months with a break

from production and a cost of $ 10,000 or more. But for almost the majority it

takes 5-6 months or more.

Such financial time expenditures sharply

limit the availability of small aircraft. Although the

operation of the aircraft is comparable to the cost of maintaining a car of the

same cost.

Therefore, the creation of an aircraft that

will not require such serious costs for pilot training is one of the most

important economic task of humanity.

It should be recalled that the era of unmanned flights

was opened by the Soviet "Buran" in November 1988 (that is, more than

30 years ago) with a processor on discrete elements with a clock frequency of 4

MHz, inferior in performance to a modern processor installed in your washing

machine, about 10 once.

Justification of

the choice of technical solutions that provide advantages over analogues or

alternative solutions:

|

The use

of an oblique wing is an innovative technical solution in this application context.

Although the oblique flow effect has long been known and well-studied and is

used in aviation, as a rule, for horizontal tail: The

advantages of the proposed aerodynamic design: 1)

Allows avoiding the disadvantages of convertiplanes, and provides high

stability during the transition from vertical flight to horizontal flight and

vice versa. 2)

Simple structure, fixed pitch propellers, cheap production and operation. No additional push screw. 3) High level

of security. Ability to continue flight and landing in airplane mode in case

of failure of 2 engines out of 4 or 5 out of 8. Time-limited continuation of

the flight and regular landing on batteries in case of generator failure.

Automatic search for a suitable landing site, proprietary software. Mandatory

installation of a rescue parachute. Possibility of equipping with car-type

airbags. 4)

Placing the wing in an oblique flow, we do not fight with turbulence, but use

them. This provides a higher aerodynamic stability compared to a pusher

propeller design. Since vertical propellers, hangers and other external

elements in horizontal flight mode create parasitic turbulences that have to

be reckoned with, and the greater the higher the speed. And in any case, they

reduce the efficiency (aerodynamic quality) of the aircraft, and are also an

additional element affecting the stable behavior of the aircraft in flight

and, ultimately, on flight safety. 5)

Extremely simple control with one joystick. 6)

Duplicated, fully electronic control of all flight modes, including emergency

ones. 90%

of all aviation accidents are human factors. 7)

Equipped with Airborne Collision Avoidance System (TCAS) and S-mode

transponder as well as LIDAR-type laser surround scanner The

project is aimed not at lengthy scientific research, but at the use of a set

of proven engineering solutions, structures and materials that have proven

their effectiveness, are mass-produced and used in light aircraft. That will allow launching production as soon as possible. |

Сontacts: info@pepelats.su

the program for calculating the route bypassing

the no-fly zones